Gases

From industrial to specialty, DeLille Oxygen gases are available in a wide range of purity and sizes.

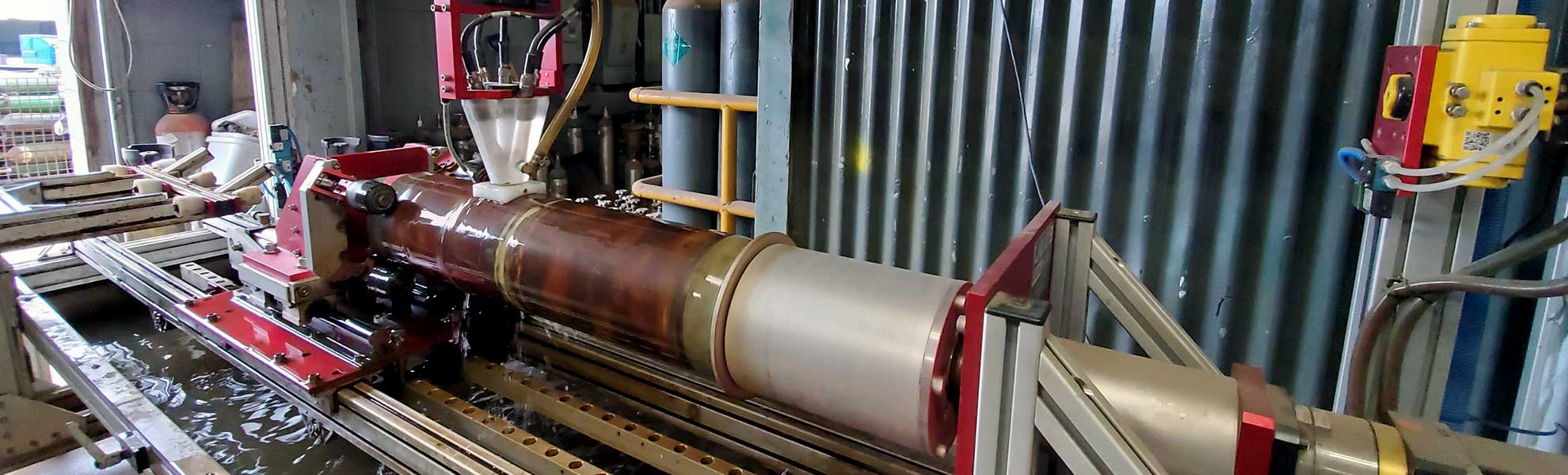

Hardgoods

DeLille Oxygen Company is your leading source for welding and gas industry-related equipment

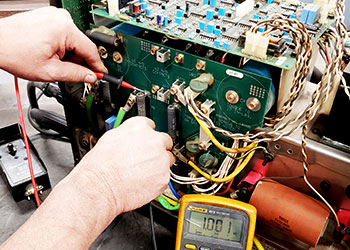

Service

With an experienced team of technicians, DeLille is your choice for equipment repair and rentals.

DeLille’s focus has and will always be being innovating for our customers by evaluating every process we or our customers are doing and making sure it is the best solution.